Mixing high- and medium-pressure fittings or incompatible parts makes systems unstable, inefficient and potentially dangerous. At worst, it can cause a potentially fatal explosion.

KC Controls are all about making our products as safe as possible and helping customers to minimise risk. Safety doesn’t happen by accident, we will explore all you need to know about avoiding the risk and what to do if you come across a mixed-pressure connection that could be hazardous.

Dangerous connections

Our engineers have recently come across situations where customers have created system connections using components with different pressure ratings. These instances are rare, but they can and do happen; creating unnecessary risks for everyone using the system. If a medium-pressure tube is machined with high-pressure tooling, this reduces the wall thickness below safe limits and can lead to catastrophic failure. Similarly, combining a high-pressure fitting with a medium-pressure tube means the male and female connections will not fit correctly. It may seem like the threads match, but the gland nuts will not engage to the required depth for the system to remain safe. The mechanical properties of the metals used in high and medium-pressure fittings are very different, meaning medium-pressure units cannot withstand the application of high-pressure. Different pressure-rated fittings just don’t mix, and there’s no safe way to combine medium and high-pressure elements. Mixing different types of connections, product lines or parts from different manufacturers is also dangerous and removes any warranties. Remember, just because something “can be done”, doesn’t mean that it “should be done!”

How it happens

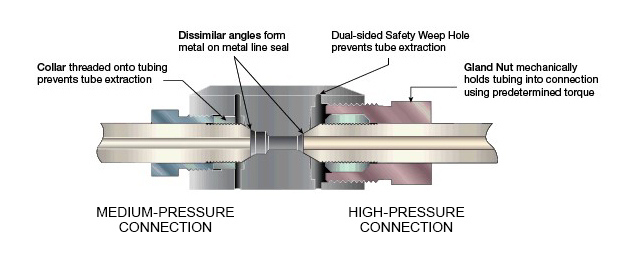

The diagram below shows how the positions of collars and glands are different, depending on the pressure of the connection.

Fig. 1. The difference in positions of collars and glands in medium and high-pressure connections.

Avoiding and reducing risk

We recommend that you never mix together:

- High pressure and medium-pressure Parker Autoclave Engineers parts.

- Parker parts with those from other manufacturers.

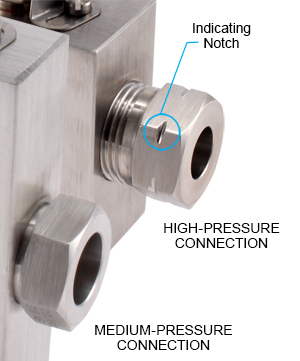

All Parker Autoclave Engineers fittings carry our manufacturer’s name, part number, material, heat code, and maximum pressure rating. We also make it easy to distinguish between different pressure ranges by clear notch markings on high-pressure nuts. Parker Instrumentation specialist SBEx (Small Bore Expert) safety training on correct and safe assembly of instrument connections to improve safety and skills across the engineering sector.

Fig. 2. Notch marking on Parker Autoclave Engineer’s high-pressure fitting nuts provides differentiation from Parker’s other pressure fittings.

Making a safe connection

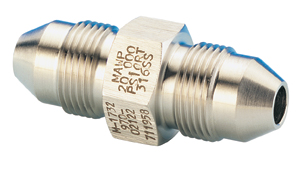

If you need to assemble medium-pressure with high-pressure in one system, we recommend the use of Parker adapters. For safety reasons, the Maximum Allowable Working Pressure (MAWP) rating is based on the lowest rating of any component (Maximum 20,000 psi).

Fig 3. Male-to-male medium-pressure to the high-pressure adapter.

The second adapter (Fig. 4) overcomes the problem of the final rotational position not being predictable, making it safe and practical to use when positioning elbow/tee fittings and valves.