The Flowline Series is a range of rugged inline mechanical flowmeters that provide visual indication of fluid flow in hydraulic systems. Capable of measuring flows ranging from 1 – 360 L/PM. Maximum allowable working pressure: 350 bar (5076 psi).

The Parker Flowline Series comprises a wide range of inline mechanical flow measurement devices designed for high-flow, high-pressure applications, including off-road mobile pump performance / industrial oil supply lines. The flowmeters are non-intrusive (i.e. do not obstruct flow) and are available with either a brass or stainless steel housing, making them suitable for use in harsh environments, where high-pressure and corrosive chemicals can damage conventional measurement devices.

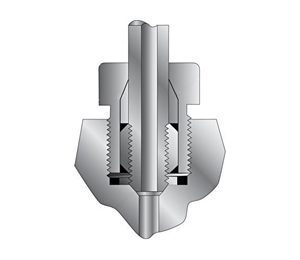

Easiflow flowmeters are highly simplistic and versatile devices that utilize a variable-orfice aperature (i.e. variable area principle). The meters can work in any plane and feature an internal piston, which moves as flow rate increases, opening a larger area to pass flowing air, water or hydraulic oil. The design provides users with a direct visual indication of flow rate and serves as a highly reliable method of measuring flow in high-pressure fluid systems.

As an option, the meters can be equipped with a magnetically-operated reed switch that’s capable of controlling valves and/or pumps, or activating alarm signals in the event that flow exceeds or drops below a pre-determined level set by the user.

Multiple Flowline meters are available to meet the unique fluid flow requirements of customers’ systems. Flow rates range from 0.2 – 360 L/min (.05 – 95 GPM), with a maximum allowable working pressure of 350 bar (5000 psi). All Flowline devices are calibrated for both oil and water and feature accuracy and repeatability of +-5% full scale defection (FSD) and +-1% FSD, respectively. The meters are relatively insensitive to viscosity changes.

Manufactures Information