For more information on ABB products or KC Controls services contact us below and a member of our team will be in touch. More Articles ...

Showing 10–18 of 64 results

Parker Bestobell is one of the world’s experts in designing and manufacturing reliable, high performance cryogenic valves for the transportation, storage, and processing of ultra-low temperature liquefied gases.

The company has provided cryogenic industrial gas flow control solutions for over 150 years, serving major gas companies and Original Equipment Manufacturers (OEM) worldwide.

The range has been designed to meet industry requirements to withstand temperature changes, possible expansion, and contraction movements generated, avoiding the deformation of its mounting. It covers all the pressure requirements for ASME B31.3 & BS EN 1626 Cryogenic Standards up to class 300. The bore sizes start at DN6 (1/4”) and are offered in increments up to DN150 (6”). Many of the valves were designed to meet specific customer needs. Parker’s primary philosophy is to build reliable, efficient, cost-effective cryogenic equipment for the intended application.

Manufactures Information

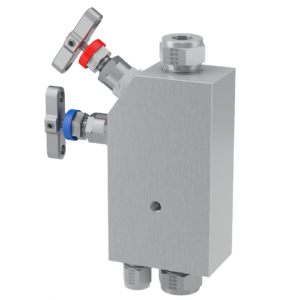

Parker’s remote and direct mount manifolds are one of the most extensive in the process instrumentation industry and accommodates all types of instrumentation installations, specifications and applications. There is a choice of single-isolate-and-vent, double-isolate-and-vent, double-isolate-and-equalise, and double-isolate-equalise-and-double-vent block configurations. All needle valves in Parker’s H series manifold valves have PTFE seats and gland packing as standard, with PEEK seats and graphoil gland packing options.

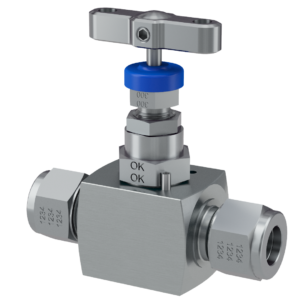

The needle valves use a standard globe style bonnet design for safe, reliable and repeatable performance. They feature an anti-blowout stem, a self centering, non-rotating spindle tip and an externally adjustable gland. As standard, the needle valves have metal-to-metal seats to ensure 100% bubble-tight shut-off, and PTFE gland packing. Graphoil gland packing and PEEK or PCTFE soft tips for gas applications are available. Further options include anti-tamper spindles, as well as lockable handwheels and T-bars.

Most of the valves and manifolds in this series are manufactured from 316 stainless steel. Oxygen clean, NACE compliant and other types of materials are also available. As standard, the components have a maximum working pressure of 10000 PSI (689 bar). The operating temperature range depends on the type of valve seat and gland packing material that is specified.

Markets:

• Oil and Gas Offshore

• Oil and Gas Onshore

• Petrochemical

• Chemical

Bar stock needle valves are purpose designed valves for operation with any fluid up to 6,000 psig (414 barg) rating. Complete with standard PTFE gland packing and self centering non rotational tip, gives the user assurance of total in service sealing security. For gaseous application soft tipped optional seating is available. A wide variety of end connectors are offered for all types of installation. NACE compliant materials and oxygen clean are also available along with an extensive list of materials of construction.

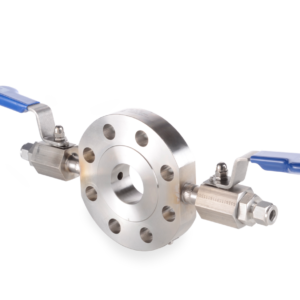

Parker’s bar stock multi-port gauge valves with two side ports designed for safe isolation and control of flow to pressure measuring devices and venting or draining of trapped process media. Available in pressure ratings up to 6,000 psi and 10,000 psi.

Parker’s multi-port gauge valves are needle type valves designed for safe isolation and control of flow to pressure measuring devices, typically a gauge, switch or transmitter. The venting or draining of trapped process media between the valve and device is also enabled, as well as the possibility of installation of two devices.

For more information on ABB products or KC Controls services contact us below and a member of our team will be in touch. More Articles ...

For more information on Parker products or KC Controls services please call 01293 538940, or fill out the form below and a member of our team will be in touch. More Articles ...

The PGS300 Gauge Pressure Transmitter is ABB’s first instrumentation product with an Environmental Product Declaration (EPD) Based on the product’s Life Cycle Assessment (LCA), the EPD is a declaration of the product’s environmental impact from resource extraction to...