KC Controls is pleased to announce that we have joined the Hydrasun Group, a leading provider of integrated fluid transfer, power, and control solutions to the global energy industry. This exciting development marks a new chapter in our journey as we...

Flanged Valves

Showing all 8 results

-

Sale!

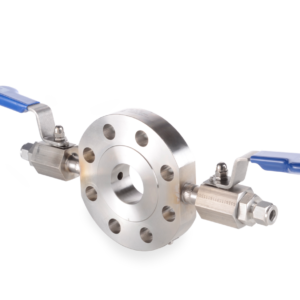

Flushing Ring

Original price was: £1,000.00.£800.00Current price is: £800.00.- Integral welded valves, no threads or PTFE required

- Easy to fit with through holes for studding

- Captive stud option

- Weld extensions gives added clearance away from chemical seal

- Available in a range of corrosion resistant alloys

-

Sale!

Monoflange

Original price was: £1,000.00.£800.00Current price is: £800.00.- Compact double block and bleed valves, featuring needle valves

- Reducing installations cost while improving safety through a reduction in leak paths

- Configurable options include single block, double block and double block and bleed

- Available in a range of material including carbon steel, stainless steel, duplex, alloy 625

-

Sale!

Monoflange & Pro-Bloc

Original price was: £1,000.00.£800.00Current price is: £800.00.- ISO 15848 approved

- Highest possible ‘A’ class leakage rates achieved

- All threads sealed from the media

- All ball valves are bi-directional

- Firesafe design available

-

Sale!

Pro-Bloc

Original price was: £1,000.00.£800.00Current price is: £800.00.- Compact double block and bleed valves, featuring needle or ball valve options

- Reducing installations cost while improving safety through a reduction in leak paths

- Configurable options include single block, double block and double block and bleed

- Available in a range of materials including carbon steel, stainless steel, duplex, alloy 625

- Manufactured from forgings to give high tensile strength through improved grain structure

-

Sale!

Pro-Bloc EP Series

Original price was: £1,000.00.£800.00Current price is: £800.00.Parker EP series process to instrument valves locate directly onto the process pipeline and facilitate a double block and bleed function for the safe removal of pressure measuring instrument (transmitter or gauge). This is done by isolating the primary block valve, opening the vent to remove the pressure within the instrument , then closing the vent and isolate the secondary block valve. The transmitter (or gauge) can now be safely removed for replacement or calibration in a workshop. The calibrated or replacement transmitter is then re installed and the block valves returned to the open position to resume the instrument function of pressure measurement. The Parker EP series combines 2 block and one bleed valve into a single body. This reduces space, weight, potential leak points and additional costs all associated with the traditional method of combining single flanged block valves to create the double block and bleed function.

The EP series is designed to the EEMUA 182 design code giving the operator and owner assurance of a valve designed to sound engineering practices. Parker offer these valves in many configurations in a wide variety of materials commonly used in industries today. They are manufactured in our UK ISO 9000 compliant facility. The valves are offered with both screwed ends such as NPT Female for direct mount of the instrument or when remote mount is required we offer integral compression fitting ends to facilitate the tubing. The integral compression ends (two ferrule A-LOK or single ferrule CPI) removes the need for NPT, thus removing potential galling, thread tape or sealant, additional leak paths and at the same time reduces the costs associated with buying and installing a separate fitting.

-

Sale!

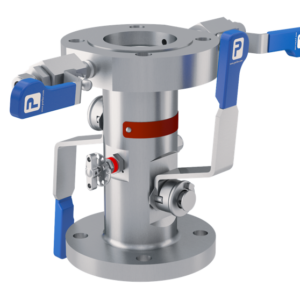

Pro-Bloc FP Series

Original price was: £1,000.00.£800.00Current price is: £800.00.Parker’s Pro-Bloc® FP series valve with floating ball design utilising both soft seats and metal seats for bubble tight sealing. The valve performs double block and bleed valves function and consists of two separate isolating ball valves and one drain valve in one single unit. This three piece construction offers space and weight saving benefits over the traditional method of using three separate valves in process piping applications. These valves are supplied to the API 6D standard.

-

Sale!

ProBloc TP Series

Original price was: £1,000.00.£800.00Current price is: £800.00.Parker’s ProBloc TP series trunnion mounted valve with a low operating torque is available with either soft or metal seat options for bubble tight sealing, spanning a wide range of pressures and temperatures.

The valve performs double block and bleed valves function and consists of two separate isolating ball valves and one drain valve in one single unit. This three piece construction offers space and weight saving benefits over the traditional method of using three separate valves in process piping applications.

These valves are supplied to the API 6D standard. -

Sale!

ProSpool

Original price was: £1,000.00.£800.00Current price is: £800.00.- Single piece forged body

- Flushing valves can be either ball or needle

- Optional captive studs on outlet. Reduction in install time, reduces costs.

- Flushing valves are available with compression fitting end removing NPT threads

- Flush valves can be factory welded thus removing NPT threads and guaranteeing valve handle orientation

- Outlet bore is machined to give maximum flushing potential