The phenomenon of stress cracking corrosion in stainless steel has been known for many decades now. Less well considered, though, is its impact on instrumentation fittings in high-pressure applications in corrosive environments. Under certain conditions, stress...

ABB

Showing 136–144 of 186 results

-

Sale!

QR Code Assistance

Original price was: £1,000.00.£800.00Current price is: £800.00.ABB’s Dynamic QR Code assistance for analyzers is a unique feature enabling comprehensive product health check and effective troubleshooting, without physically connecting to your system.

In addition to providing static information for analyzer identification, the QR code contains dynamic information on system configuration and current

health status. ABB specialists are able to use this data to identify the problem and provide a rapid response solution.ABB’s QR Code assistance for analyzers is very simple, follow these steps:

1. Error occurs causing the analyzer to display, maintenance request or error.2. Access the QR code page on the device display.

3. Open the myIB app on your mobile device, scan the QR code and send data to the ABB team.

4. ABB service specialists review the data and troubleshoot the problem.

5. ABB provides an action plan to fix the problem. The customer only needs a QR code reader app or to download the new ABB myIB app.

-

Sale!

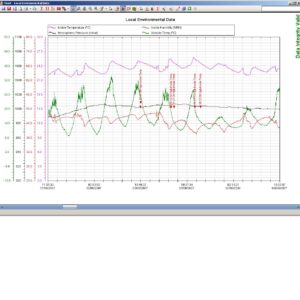

RDM500

Original price was: £1,000.00.£800.00Current price is: £800.00.DataManager Pro is an application that creates a database of recorded data providing secure long-term storage and enabling instant access to data regardless of when or on which ScreenMaster it was recorded. The archived data can be transferred to DataManager Pro either manually, via the ScreenMaster’s memory card, or automatically, via Ethernet communications. The stored data can be displayed in both tabular and graphical format and analyzed using the extensive array of tools provided.

Manufacturers Information -

Sale!

Rl100

Original price was: £1,000.00.£800.00Current price is: £800.00.Radar level detection for liquids and solids. Stable reading in the most challenging environments.

- Used when second 4-20 mA (analog) output is required

- LCD display

- Field replaceable module

- Simple Calibration

- Dual compartment housing with separate field terminal compartment

- Built in RFI/EMI filter

- 2i. stainless steel pipe stand mounting bracket

- Glass viewing window

-

Sale!

RVG Retrofit

Original price was: £1,000.00.£800.00Current price is: £800.00.When replacing a C1900 paper recorder with a new RVG200 videographic controller many are unsure how to mount the unit in an existing enclosure. Our sister company, KCS can provide a modified new C1900 enclosure housing the RVG200 complete with terminals and recorder wiring.

- Same panel mount aperture and fixing holes

- Terminals located to minimise on-site wiring.

- Enables easy access to rear terminals for calibrations

- Provides secondary protection of recorder in harsh environments

-

Sale!

RVG200

Original price was: £1,000.00.£800.00Current price is: £800.00.The RVG200 recorder takes the established operating and security benefits of the ScreenMaster range one step further. Features include touchscreen ‘swipe’ operation, front and rear USB ports for connecting peripheral devices, including a barcode scanner and keyboard, and Ethernet and RS485 communications.

Up to 24 process signals can be connected to the RVG200’s analog inputs or transferred to it via digital communications.

Manufacturers Information -

Sale!

Sanitary application thermometer SensyTemp TSHY

Original price was: £1,000.00.£800.00Current price is: £800.00.Thermometers for food and beverage engineering. It communicates with 4 to 20 mA or direct sensor output. Rough environmental conditions, space-saving installation and flexible assembly are only some examples of the skills of our daily approved reliable temperature sensors.

-

Sale!

SensyTemp TSH200

Original price was: £1,000.00.£800.00Current price is: £800.00.Straight thermocouples for high temperature applications in industrial furnaces, combustion processes and melting processes. It communicates via FOUNDATION Fieldbus, PROFIBUS PA, HART, 4 … 20 mA or direct sensor output.. Approved ABB typical modular system:

- TSH210 with metal thermowell, for temperatures up to 1300 °C (2372 °F)

- TSH220 with ceramic thermowell, for temperatures up to 1800 °C (3272 °F)

- TSH250 with platinum sleeve, for temperatures up to 1650 °C (3002 °F)

- suitable to main process connections

- suitable to main process control systems

-

Sale!

SensyTemp TSP100

Original price was: £1,000.00.£800.00Current price is: £800.00.Temperature sensors for for standard application.

The main application for this RTD or thermocouples temperature sensors is pipe and tank engineering. Suitable for low and medium process requirements. It communicates via FOUNDATION Fieldbus, PROFIBUS PA, HART, 4 … 20 mA or direct sensor output.

-

Sale!

SensyTemp TSP300

Original price was: £1,000.00.£800.00Current price is: £800.00.SensyTemp TSP300 series sensors allow for measuring inset replacement during operation. With their short response time and high vibration resistance these devices meet the most demanding process requirements.

- TSP311 without thermowell

– Insertion in an existing thermowell - TSP321 with welded tubular thermowell

– Screw-in thread, flange, compression fitting - TSP331 with drilled thermowell

– Screw-in thread, flange, weld-in socket

- TSP311 without thermowell