Measurement performance at the speed of light Connection made easy! The first flow measurement devices leading the way The business case for digitization is undisputed Power over Ethernet Omits the need for a separate DC power infrastructure...

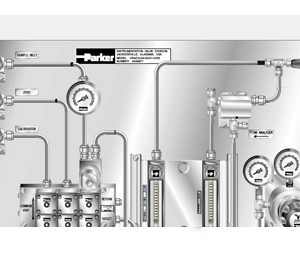

Parker

Showing 163–171 of 173 results

-

Sale!

Tube Cutters

Original price was: £1,000.00.£800.00Current price is: £800.00.- Adjustable tube cutters are designed to produce square cut ends with no external burr and minimum internal burr when used on fully annealed copper, brass, aluminium and steel tube.

- Features a hardened and burnished tool-steel cutting wheel and a flare cut-off groove in roller.

- The handle feeds and adjusts the cutting wheel to uniformly cut tube as the cutter is rotated.

-

Sale!

U Series

Original price was: £1,000.00.£800.00Current price is: £800.00.- Stem packing below the threads isolates the thread lubricant from the flowRoddable, straight through flow path

- Severe service applications

- Panel mountable

- Ideal for steam blowdown

-

Sale!

Ultra High Pressure

Original price was: £1,000.00.£800.00Current price is: £800.00.Parker Autoclave Engineers High & Ultra High Pressure connections are a refinement of the original cone & thread joint which has been the standard connection in high pressure technology since its development by an agency of the US Government over 75 years ago. This design set precedence of quality and reliability found in all Parker Autoclave Engineers products to this day.

The pressure handling capabilities of this connection design have been applied successfully to control pressures up to 150,000 psi. All-metal sealing and working temperatures from 0° to 600°F (-18° to 315°C), along with a variety of different material options make this connection one of the most versatile ever. Fittings and tubing found in this section are designed using ASME B31.3 Chapter IX standards to be compatible with all of our Ultra High Pressure Valve and Fitting configurations.

-

Sale!

Ultra High Pressure Tubing

Original price was: £1,000.00.£800.00Current price is: £800.00.Parker Autoclave Engineers offers a selection of austenitic cold drawn stainless steel tubing designed to match the performance standards of Parker Autoclave valves and fittings. Parker Autoclave ultra high pressure tubing is manufactured of 316/316L (UNS S31600/S31603) or HP160 (100Ksi only) specifically for high pressure applications requiring both strength and corrosion resistance. The tubing is furnished in random lengths between 20 feet (6 meters) and 26.5 feet (8.0 meters). The average is 24 feet (7.3 meters). Our HP160 tubing was designed by Parker Autoclave Engineers specifically for High Cyclic use such as Waterjet cutting machines.

Manufactures Information -

Sale!

Ultra-Seal™ Constant Pressure Cylinders

Original price was: £1,000.00.£800.00Current price is: £800.00.- 316 SS shut-off valves on each end with Acetal Resin soft seats and PTFE Pressure-Core® stem seals — standard with 5-year no-leak warranty

- Meets the requirements of NACE MR0175/ISO 15156-3

- Burst disc holder and 2,000 PSI SS pressure gauges

- Mag-N-Tube™ volume indicator

- Gas and liquid designs

- Patented piston with ceramic magnets and magnetic field intensifier

- DOT approved 300cc to 1000cc

- Optional 80% fill switch provides additional operator safety

- CRN — Canadian registration certificates available

-

Sale!

V Series

Original price was: £1,000.00.£800.00Current price is: £800.00.- For positive leak tight shut-off and regulation of fluids

- Choice of three stem types

- Wide variety of size and end connections

-

Sale!

Valairdata 4 – Sterile Gas Filter Integrity Testing Unit

Original price was: £1,000.00.£800.00Current price is: £800.00.Valairdata 4 is the next generation of fully automated aerosol challenge integrity test unit, designed to test the integrity of sterile gas filters quickly and easily.

The Valairdata 4 aerosol challenge test is fully correlated to aerololized B. diminuta, B subtilis and Enterobacteria phage MS2 challenges and is a recommended test methodology in the PDA’s “Sterilizing Filtration of Gas – Technical Report #40”.

The unit utilizes Parker’s 50 years of experience in the provision of world leading sterile gas solutions by further improving the usability and sensitivity of the test process and offers significant savings in operator time.

-

Vent Master

Parker’s VentMaster is an easy to operate “all in one “system. After a process sample stream is analyzed, it must be disposed of in a manner consistent with environmental regulations. It has been common practice to simply vent the sample stream to the atmosphere. As environmental regulations become more stringent, it is becoming undesirable, if not illegal, to admit these samples to the atmosphere. For an analyzer to operate correctly, it must be calibrated and operated under the same conditions.

Manufactures Information -

Sale!

Vent Recovery Panel

Original price was: £1,000.00.£800.00Current price is: £800.00.- Pre-engineered compact instrument panel that includes fittings, valves, stream switching valve, regulators, and gauges

- System adjust for variations in gas supply pressures and flows