KC Controls is pleased to announce that we have joined the Hydrasun Group, a leading provider of integrated fluid transfer, power, and control solutions to the global energy industry. This exciting development marks a new chapter in our journey as we...

Non-Invasive Ultrasonic Flowmeters

Showing all 7 results

-

Sale!

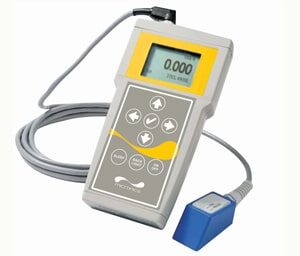

8812 Ultrasonic Pipe Thickness Gauge

Original price was: £1,000.00.£800.00Current price is: £800.00.A very useful tool used to determine the internal diameter of pipework on existing installations, an essential parameter for accurate clamp-on flow measurement.

- With wall sound speed feature.

- Quick and easy setup.

- 11 Types of Materials.

- Battery powered.

-

Sale!

Portaflow D650 Doppler Flow meter

Original price was: £1,000.00.£800.00Current price is: £800.00.The Portaflow D650 ultrasonic sensor injects high-frequency sound through the pipe wall and into the flowing liquid. Gas bubbles or solids suspended in the liquid reflect the ultrasonic signal to the sensor. When this sound is reflected from moving bubbles or particles it is returned to the sensor at a shifted frequency. This frequency shift is called the Doppler effect. The PF D650 continuously measures the change from its transmitted frequency to the received frequency to accurately measure flow.

-

Sale!

UF D5500 Fixed Clamp-on Flow Meter

Original price was: £1,000.00.£800.00Current price is: £800.00.Best value fixed non-invasive, clamp-on, measurement solution for dirty water applications.

- Liquids, Sludge & Slurries, Solvents, Pulp Stock, Food Products, Lubricating Oils & Crude Oil.

- To suit pipes 12.7mm-4500mm

- No Pipe cutting, No contact, Non-invasive sensing

- Easy to use

- Watertight enclosure

- 26 million point data logger now as standard

- Improved signal stability

- Enhanced diagnostics

- Modbus and HART serial communications now optional feature

- Best value solution for “dirty” liquid monitoring including: Raw Sewage, Viscous

-

Sale!

UF3300 Fixed Clamp-on, Heat/Energy, Flow and Process Measurement Meter

Original price was: £1,000.00.£800.00Current price is: £800.00.ULTRAFLO UF3300 clamp-on flow energy/heat and process measurement meters from Micronics, for simple, accurate floe and energy measurement from outside the pipe.

Our fixed flow and energy/heat meter solutions for closed pipe applications are ultrasonic, clamp-on and non-invasive, This means considerable savings from no cutting pipes or downtime interruption to process whilst the meters are being installed and low operation costs ie no in-line blockages and dry maintenance. The ULTRAFLO UF3300 brings simplicity to the non-invasive measurement of liquid flow and hydronic energy. It offers the user quick and accurate flow and energy measurement. And with its easy to follow menu and simple set up results can be achieved in quick time.

Application/use: Include Process fluid measurement, HVAC/Building Services metering, District Heating Network monitoring, Ultrapure water measurement and Heavy fuel oil metering,

-

Sale!

ULTRAFLO U1000MKII-FM Fixed, clamp-on, pipe mounted, ultrasonic flowmeter

Original price was: £1,000.00.£800.00Current price is: £800.00.The New ULTRAFLO U1000MKII-FM is a Fixed, clamp-on, pipe mounted, ultrasonic flow meter, which delivers significant installation savings and non-invasive, dry servicing benefits for pipe sizes ranging from 22mm – 180mm (6″) OD.

-

Sale!

ULTRAFLO U1000MKII-FM-WM Clamp-on Flowmeter with Wall Mounted Kaypad and Display

Original price was: £1,000.00.£800.00Current price is: £800.00.The ULTRAFLO U1000MKII-FM-WM is a Clamp-on, Ultrasonic flow meter with a separate wall mounted keypad and display, a “Best Value” alternative to traditional in-line flow meters, for commercial and industrial water flow measurement applications. Offering significant installation cost and dry maintenance benefits over traditional in-line products.

-

Sale!

UX5000 ATEX Clamp-on Flow Meter

Original price was: £1,000.00.£800.00Current price is: £800.00.A flow meter is a device that measures the rate of liquid flow, providing essential data for monitoring and controlling various processes such as industrial manufacturing, water treatment, HVAC systems, and oil refining, where accurate measurement of fluid flow is crucial for efficiency and quality control.

The UX5000 uses a cross correlation transit time algorithm to provide accurate flow measurements. An ultrasonic beam of a given frequency is generated and applied to the transducer crystals. This transmission goes first from the downstream transducer to the upstream transducer as shown in the upper half. The transmission is then made in the reverse direction, being sent from the upstream transducer to the downstream transducer. The speed at which the ultrasound is transmitted through the liquid is increased slightly by the velocity of the liquid through the pipe. The subsequent time difference T1-T2 is directly proportional to the liquid flow velocity.