News Category:

ABB paperless recorders help ensure round-the-clock quality control of meat products

A manufacturer and supplier of meat products to the food industry is using two ABB RVG200 paperless data recorders to help ensure its products are produced to the highest levels of safety and quality. Used by the food producer to monitor and record temperatures in...

read more

Medium Pressure Safety – All Tubing is Not Created Equal

In industrial applications where high pressures (over 6,000 psi) are used, safety is of paramount importance. Even well below these pressures, precautions are needed to ensure a safe working environment. Tubing from different manufacturers may look the...

read more

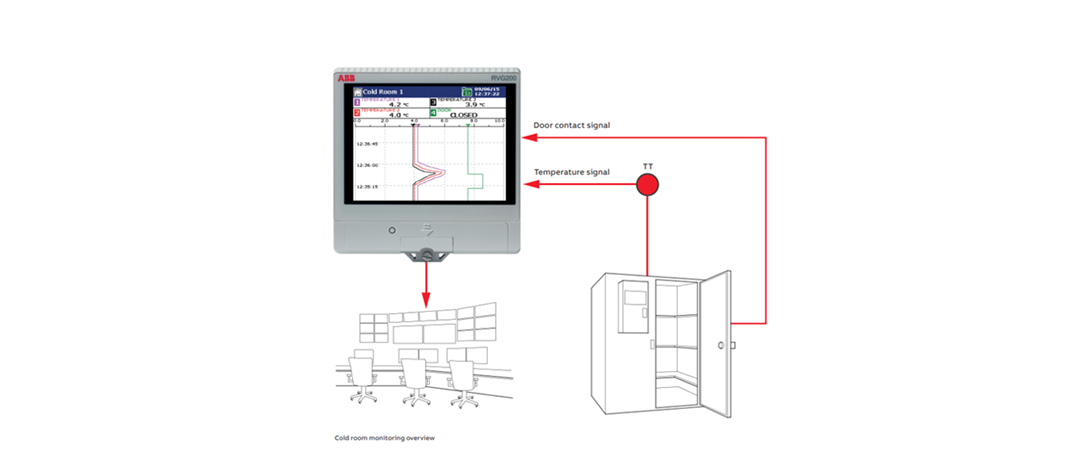

Temperature monitoring in fridges, freezers and cold rooms

Companies are obliged to monitor cold storage areas, particularly those used for storing frozen foods (for example, ice cream, meat and fish) and chilled products (for example yoghurt, prepared meals and cheeses). Examples of typical minimum storage temperatures are:...

read more

Protecting the Flavour of Craft Beers – the Benefits of Sterile Filtration

As new markets emerge and off trade consumption increases, the shelf-life of canned and bottled craft beer has become increasingly important. Brewers of craft beers carefully select and balance the ingredients to generate the unique and distinctive characteristics of...

read more

Ensuring production line equipment safety remains a core consideration

Despite the best efforts of manufacturing companies, problems with product quality can and do occur that can potentially have both reputation and financial consequences. Batch monitoring and recording can help to ensure that, in the event of a problem, the affected...

read more

Ricky & Pat Retire

It is very unusual to have two people retiring at the same time, but after 29 and 10 years of dedicated hard work with KC Controls, husband and wife Ricky and Pat are setting their sights on a well-deserved retirement to spend more time exploring new adventures. After...

read more

Foam Measurement and Control with Lasers

Laser transmitters have been applied with great success in the measurement and control of foam, which is an integral part of many industrial processes. Foaming can be present in many industrial processes like water & wastewater treatment, oil & gas, food & beverage,...

read more

Can a flowmeter bridge the IT/OT divide?

If marketplace adoption is the primary judge, then the process industry's first-generation digital fieldbus standards significantly underachieved. Indeed, the venerable 4-20mA analog standard, augmented by HART, remains the predominant field communications modality....

read moreIt’s Time to Recognise Integral Ended Connections on Instrument Manifolds

Securing leak-free connection of impulse lines to manifolds for applications that use differential pressure flowmeters is a subject that has taxed instrumentation engineers for more than a century. Back in 1910, when the very first orifice plate installations made an...

read more

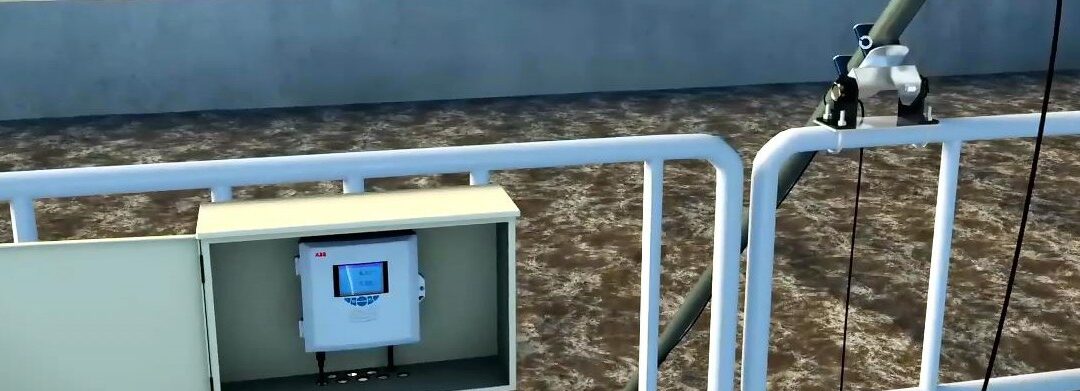

Why it’s Time to Embrace the Digital Measurement Revolution for Improved Wastewater Treatment

Developments in digital technology have opened new possibilities for water sensing, offering unprecedented access to a raft of real-time, high accuracy data without the drawbacks associated with many conventional sensor types. By utilising these devices in their water...

read moreLatest News

Streamline your Operations and Prepare for the Future of Flow Measurement

The ABB CoriolisMaster and ProcessMaster flowmeters combine Power Over Ethernet (PoE) with the ProfiNet protocol, providing a single-cable solution for both power and data transmission. Key benefits you can expect: Flexibility at Your Fingertips: Our integrated web...

How do I find the right level product? Which level measurement method is right for my process?

Are you looking for the right level product for your measuring task? As a manufacturer of level products based on various measuring methods, we are happy to support you in this search with our expertise. The choice of level measurement technologies is vast – contact...

How to digitalize asset performance management for instrumentation

ABB’s Sabyasachi Bhattacharyya explains how ABB’s digital suite connects the physical and digital worlds to help industrial players better manage their installed base of instrumentation devices and get better actionable insights that lead to increased efficiency and...